(text and background only visible when logged in)

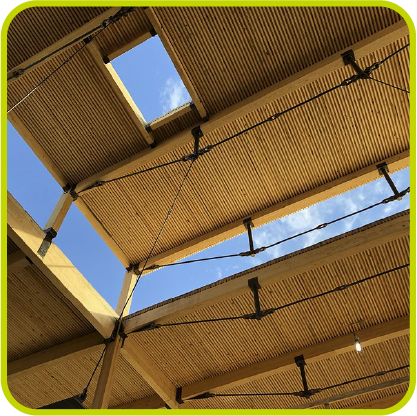

Photo courtesy of Miller Hull Partnership

Endorsing Products That Are Safe for All Species Through Time

The Materials Petal aims to eliminate harmful materials and foster a responsible materials economy through five key Imperatives:

- Red List-free materials

- Locally sourced materials

- Embodied carbon tracking

- Use of salvaged and responsibly sourced materials

- Waste reduction during construction

This requires close coordination across all disciplines. The Kendeda Building simplified its materials palette, relying primarily on wood with minimal steel and concrete, while exposing many systems to minimize unnecessary and potentially harmful materials.

(text and background only visible when logged in)

The Red List Imperative

The Red List identifies the most harmful chemicals commonly found in the building industry—substances that pose serious risks to human health and the environment. LBC 3.1 targets 22 such chemicals, including:

- Asbestos

- Formaldehyde

- Lead

- Mercury

- PVC

How Does The Kendeda Building Accomplish This?

To comply with Red List requirements, the Kendeda Building team rigorously vetted materials, prioritizing those with Declare Labels, Healthy Product Declarations (HPDs), or Cradle to Cradle certification. The team also sought ingredient disclosures or eliminated non-compliant materials, such as removing mastic coating from underground pipes.

NOTE: The Declare program—developed by the International Living Future Institute (Living Future)—acts as a “nutrition label” for building materials. It offers an online database that helps manufacturers transparently disclose the ingredients in their products, while providing project teams with a growing list of materials that comply with the Living Building Challenge requirements. By selecting products listed in Declare, project teams can more easily meet LBC’s rigorous material transparency and health standards.

While Living Future grants exceptions when no viable alternatives exist, advocacy remains key. The Kendeda Building, for example, obtained an exception for glulam adhesives but continues pushing for safer alternatives.

Complying with the Red List is one of the most difficult aspects of the Living Building Challenge. To support other projects, we are happy to share our product list. The Bullitt Center's product list is available here.

Living Economy Sourcing Imperative

The Living Economy Sourcing Imperative promotes:

- Local economic growth

- Stronger community ties and development

- Reduced environmental impacts of transportation

Distance Requirement

To meet these goals, projects must incorporate place-based solutions that promote sustainable practices, products, and services. For LBC 3.1, projects had to meet the following distance requirements:

- At least 20% of materials should be sourced within approximately 311 miles of the project site.

- If needed, up to 30% of materials can be sourced from within 621 miles.

- An additional 25% can be sourced from within 3,107 miles.

How Does The Kendeda Building Accomplish This?

The Kendeda Building incorporated locally sourced materials, including:

- Wood and brick sourced from within the southeast United States

- Carpet, steel, glulam, nail laminated timber (NLT), and rigid insulation all fabricated or manufactured in Georgia

Embodied Carbon Footprint Imperative

The Embodied Carbon Footprint Imperative aims to reduce a building's carbon impact by minimizing emissions from materials and construction. The Kendeda Building design team prioritized wood as its primary structural material due to its significantly lower embodied carbon — one-sixth of steel or concrete. Additional carbon reduction strategies included:

- Recycling 99% of construction waste

- Using salvaged and low-carbon materials

- Achieving a 30% lower carbon intensity than the median for educational buildings

To fully offset construction emissions, the Kendeda team purchased a one-time carbon offset to fund new solar projects in India.

Net Carbon Impact Over Time

By reducing embodied carbon and generating approximately 200% net positive energy each year, The Kendeda Building’s total carbon impact—from construction and operations—will decline over time. Key projections include:

- Net-zero carbon by 2039, achieved through surplus solar electricity production (not including the carbon offsets originally purchased to meet net-zero carbon status at opening).

- A temporary increase in emissions in 2040 due to a planned building refresh, followed by continued energy surplus that will offset this impact—making the building net carbon negative by 2046.

This projection assumes the 2040 upgrade will still carry a carbon cost. By then, we hope the building industry will have widely embraced regenerative materials and carbon-neutral—or even carbon-negative—practices, potentially accelerating the timeline to a net carbon-negative future.

Responsible Industry Imperative

The Responsible Industry Imperative aims to reduce the environmental and social impacts of industries dependent on natural resource extraction and plant cultivation, including:

- Stone and rock

- Metal and minerals

- Timber

Satisfying the Requirement for Sustainable Practices

To meet this standard, LBC 3.1 projects had to:

- Advocate for third-party certified standards for sustainable resource extraction and fair labor practices

- Ensure that all non-recycled wood used in the project is FSC Certified (Forest Stewardship Council)

- Encourage stone manufacturers to pursue ANSI Natural Stone Council Standard certification

- Use at least one Declare product for every 500 square meters of gross building area

- Reach out to at least 10 manufacturers not currently using Declare, sharing program information with them

Photo courtesy of David Luffel

The Kendeda Building's Responsible Sourcing

The Kendeda Building project exemplified these principles by:

- Incorporating salvaged stone from the former Georgia Archives Building

- Sourcing structural slab stone from the Forest Park Stone quarry in Forest Park, Georgia

- Using salvaged wood and FSC certified wood throughout the project

Net Positive Waste Imperative

The Net Positive Waste Imperative aims to reduce the environmental burden associated with material extraction, processing, and disposal during construction. Or put another way, this Imperative results in net-negative construction waste by turning what would have been waste into a valuable resource.

To achieve this, project teams must create a materials conservation management plan to reduce or eliminate waste across a building’s design, construction, operation, and end- of- life phases. This approach conserves natural resources and reintegrates waste industrial loop or natural nutrient loops.

How Does The Kendeda Building Accomplish This?

In addition to implementing a waste management plan, the project diverted nearly all construction waste from landfills, meeting or exceeding these minimum thresholds:

- 99% of metal,

- 99% of paper and cardboard,

- 100% of soil and biomass,

- 95% rigid foam/carpet and insulation, and

- 90% of all other waste (combined weighted average).

To ensure success, Skanska (the general contractor) compiled a list of expected waste streams from each trade partner from the start of construction. Salvageable material were either incorporated into the project or donated to the local Lifecycle Building Center for reuse. For example, approximately 443 tons of asphalt was recycled.

By the end of construction, The Kendeda Building team prevented 99.5% of scraps and unused materials from becoming waste.

| Category | Diverted (lbs) of Material | Total (lbs) of Material | Percent Diversion Required | Actual Percent of Category Diverted |

| Metal | 75,360 | 75,360 | 99% | 100.0% |

| Paper and Cardboard | 39,540 | 39,540 | 99% | 100.0% |

| Soil and Biomass | 6,896,310 | 6,896,310 | 100% | 100.0% |

| Rigid Foam, Carpet, and Insulation | 107,800 | 110,080 | 95% | 97.9% |

| All others - combined weighted average | 2,656,000 | 2,702,280 | 90% | 98.3% |

| Totals | 9,775,010 | 9,823,570 | 99.5% |

Beyond recycling and repurposing materials during construction, Living Building Challenge-certified projects must incorporate at least one salvaged material per 500 square meters of gross building area. The Kendeda Building team embraced this principle by integrating salvaged materials from nearby demolition projects, including:

- Recycled slate used for interior wall finishes sourced from the Alumni Association roof renovation.

- The nail laminated timber pieces incorporated 25,000 feet of 2x4 from demolished film sets.

- Granite from Georgia Archives Building was used in landscaping the site.

- Storm-fallen trees (black oak, white oak, and water oak) from Georgia Tech’s campus were collected, milled, and dried for “live edge” counters, tables, and benches.

- Pieces of wood trimmed from the NLT were used for internal stairs.

- 1880s heart pine joists removed in 2016 from the iconic Tech Tower were used as stair treads.

Red List - Product Lists

The Kendeda Building team spent over two years identifying Red List-compliant products and is happy to share its product list with the following caveats:

- Some products may not be entirely Red List-free due to exemptions permitted under the Living Building Challenge, driven by market limitations (e.g., the unavailability of Red List-free alternatives).

- Proprietary claims in the industry may mean some non-compliant materials were unknowingly used.

- The team does not warranty these products.

- Other projects should conduct their own due diligence, as product formulations may have changed.

For reference, the Bullitt Center's product list is available here.

Salvaging Materials on Campus

During the 2016 renovation of the iconic Tech Tower, heart pine joists dating back to the 1880s were removed and have been repurposed as stair treads for The Kendeda Building.